Manual For Gravograph

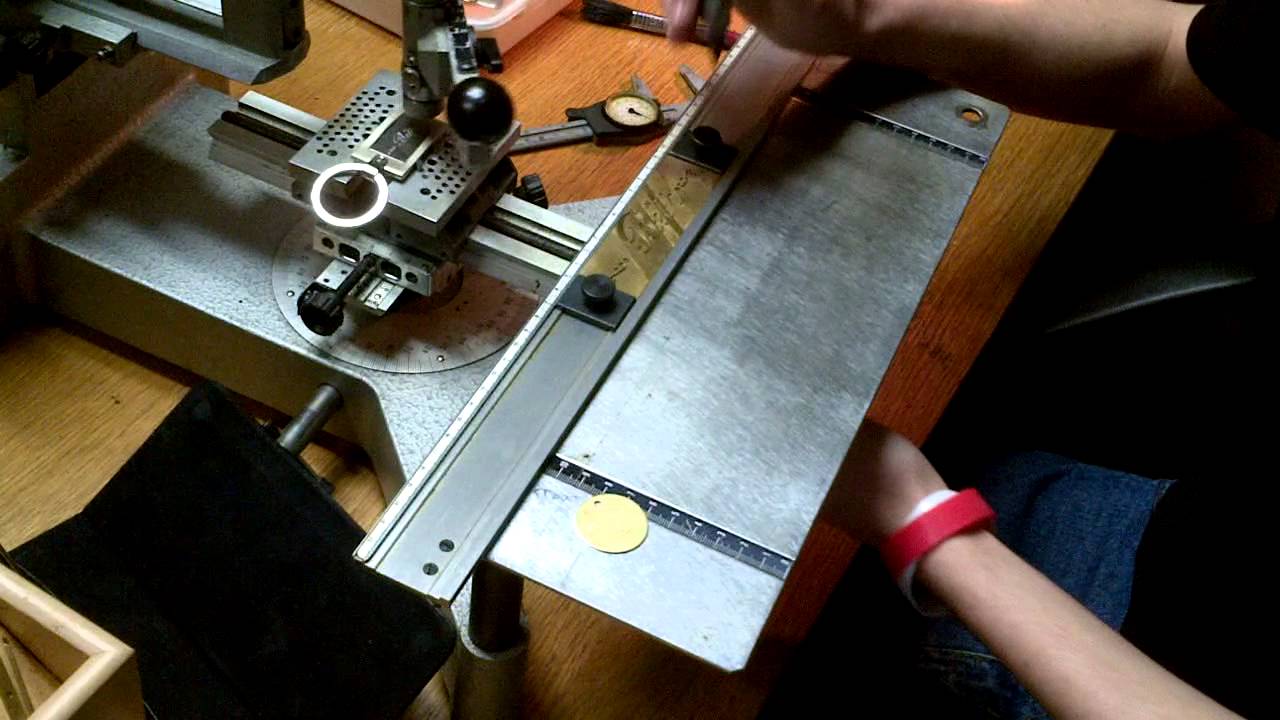

Hello, I don't suppose people use manual engraving machines any more.but basically I can't afford a CNC machine so I have to make do with a manual one for now. I bought it from Ebay and it is a a lovely solid old thing but it didn't come with a manual. Although I have got the basic idea and can engrave, I'm sure there are tecniques for measuring, enlarging and other aspects that would it a lot easier.

Does any one know where I could get a copy? I tried Engravograph website email form, but didn't get a reply, but I'm guessing I didn't get a response because the form was more related to purchasing their products. I'm not too sure where to find the model number for it either, I can only find a seiral number. Also i'm looking for fonts for it, plastic or otherwise - I've found some places that sell them but rather costly, 2nd user would be good. Any one have any ideas?

Hi, I purchased a Gravograph LS900 laser cutter/engraver from Boxford second hand in January for just short of 7,000 pounds. It was out of their showroom and only used for demonstration purposes so looked in nice condition. It came with a 6 months warranty on all parts. Worked ok for a few weeks until our first problem. The angle it was cutting at. I know that its never going to be exactly 90 degrees on larger material like 5mm acrylic because of how the beam is formed its got to be at some slight angle above and below the point where they meet. But ours was worse than this, and after looking into it we can actually see that the carriage that holds the lense is not square to the rail it moves on.

Its out by 2 degrees. Whilst we had an engineer out he agreed it was off, said he had never seen than before and it wasn't adjustable but have been like that since it was built and not noticed until now. I contacted Boxford as it was them who sold it to us but was quickly told there was nothing wrong with it and it was ok when it left them. We exchanged emails about it and within that time, we had learned how to do a few more things on the machine and learnt how to use the raster feature. The problem was that whenever it did a raster, it was leaving a vertical line either side of the object being rastered. You could see the laser was firing at the very start and very end of its travel when it wasnt supposed to be firing. Eventually, they passed it over to gravograph to send out an engineer.

When the engineer came out he agreed about the angle but said it was not adjustable and tried to correct the rastering problem. After lots of tests and changing settings, it seemed to be ok, he said he had altered the tickle setting, and it was working, until the next day. It was doing the same thing so i phoned them again. We had to wait a few weeks for the next visit, and when the engineer arrived he suspected the laser tube might be faulty, so he didnt do anything but tell us he was going to order a replacement tube but it would take a while as it was coming from france and they had to source one. About 4 weeks later they came back with a new laser tube, installed it, but couldnt get it to work.

He suspected they had sent a faulty tube, and told us we would have to get another. Weeks later, they came back and installed its 3rd tube, all seemed ok, even though it was supposed to be a 30W tube, the engineer tested it and said wow this is coming up at 40 watts too. Brilliant, we can get on with now. Nope, it had developed a new problem. Between cuts when it was vectoring, and moving from one cut line to another, the laser was firing as it moved to the next line to cut, ie when it shouldnt be, and marking the material every time it moved. We had to wait again weeks for an engineer, and when he came out he changed the USB board in the machine, messed around with some settings, and got it running whilst he was there. About an hour later, the same problem returned.

Back on the phone to gravograph, waiting weeks for a visit, they came out and said they think now that its the cable between the laser tube and the machine. Maybe thats why all the other tubes havent been successful. Again, the problem is you will have to wait a while, its got to be sourced in france then shipped over. 2 weeks later, a phone call, really sorry but they have sent in the wrong cable, we have asked for the correct one and sent them a photo to france so they know which one it is. By this time, well long before, im totally regretting the purchase and tell gravograph im going to go back to boxford as its ridicuous this. Dont worry dont worry we will get this machine running right for you. Ok, another 2 weeks and the cable comes.

The engineer visits and fits the new cable. Tests the machine, it works. Nope, one week later, the same problem, cutting when it shouldnt be. On the phone to gravograph again, we will try putting the original tube in that it came with at the same time as the new cable, we havent tried that combination yet and it may work.

So they did that, put the old tube (the original one) back in. It worked for a full 2 weeks (it was an improvement) until the problem which its currently got.

I personally think its to do with the tube again (they took this tube out and had it stored for months before putting it back) as it wont cut through materials properly any more. Ie i sent a few jobs last night and it starts of cutting ok, as i can see the flash when the beam hits the honey comb, but half way round a 100mm x 100mm square the power gets lower and lower and by the time its doing the last line of the square its just very lightly scratching the material. Ive sent the photos to gravograph today, i believe we are back at square one. As you can see from the pic, the details of the problem i describe we have now. The ones where it has cut out, i sent it round 4 times, just pressed start again when it finished, until eventually it cut through.

The settings are what it has always cut out fine with so i know we arent trying to run it too fast, infact, i slowed it down as a test and got the same result. Ive not had a reply from gravograph yet, but my warranty is up, although for 4 and a half months out of the 6 months warranty its been awaiting repair.

Im absolutely fed up with it. I purchased this one thinking it would give me the reliability i was looking for and has been a total nightmare and cost me alot of money to purchase it. Any suggestions? Im regretting not fighting for my money back at the very first warning sign, but we thought it was going to be fixed, never imagined it was going to be this much of a nightmare and drag on for so long. Similar Threads:. Newbie-.

Europe. Need Help! The tube is just a glorified light bulb, it doesn't make any decisions, run energy through it, it fires, don't run energy through it it doesn't fire. Yours is firing when it should not, different problem set from one that isn't firing when it should, problem therefore CANNOT reside in tube or wiring, problem is in controller or controller firmware or control software. The fact that the vendor and or manufacturer are apparently too thick to work this out. Re the bent by 2 degrees chassis, someone dropped it or loaded it badly. Strip it and re assemble with appropriate shims, again, the fact that the vendor and manufacturer cannot apparently work this out.

Manual Gravograph Im3

I'd have been demanding my money back, long since, sale of goods act, fitness for use, etc etc etc. Agreed with elaser. Seems like they genuinely trying to fix it but have no idea how. Cable from France is ridiculous BTW just buy a $15 off amazon or your nearest electronics store and be done with the cable theory.

Manual Gravograph Is400

All the problems you describe sound like either a transmission error, or a controller board error. Not sure why they keep tinkering with and changing tubes. Most recent error could be power supply but most likely is controller board. Stay on them this is a pre existing condition so they should cover it even if the warranty is over. Worse case if you're fed up demand a refund. May or may not happen on a used device. On used devices you assume some risk, but this sounds rather bad.

I would have asked for a refund by now, you've been pretty patient it sounds. The tube is just a glorified light bulb, it doesn't make any decisions, run energy through it, it fires, don't run energy through it it doesn't fire. Yours is firing when it should not, different problem set from one that isn't firing when it should, problem therefore CANNOT reside in tube or wiring, problem is in controller or controller firmware or control software. The fact that the vendor and or manufacturer are apparently too thick to work this out. Re the bent by 2 degrees chassis, someone dropped it or loaded it badly. Strip it and re assemble with appropriate shims, again, the fact that the vendor and manufacturer cannot apparently work this out. I'd have been demanding my money back, long since, sale of goods act, fitness for use, etc etc etc.